- Startseite

- heat exchanger

- How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred —

How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred —

4.5 (599) · € 22.00 · Auf Lager

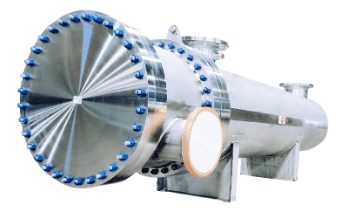

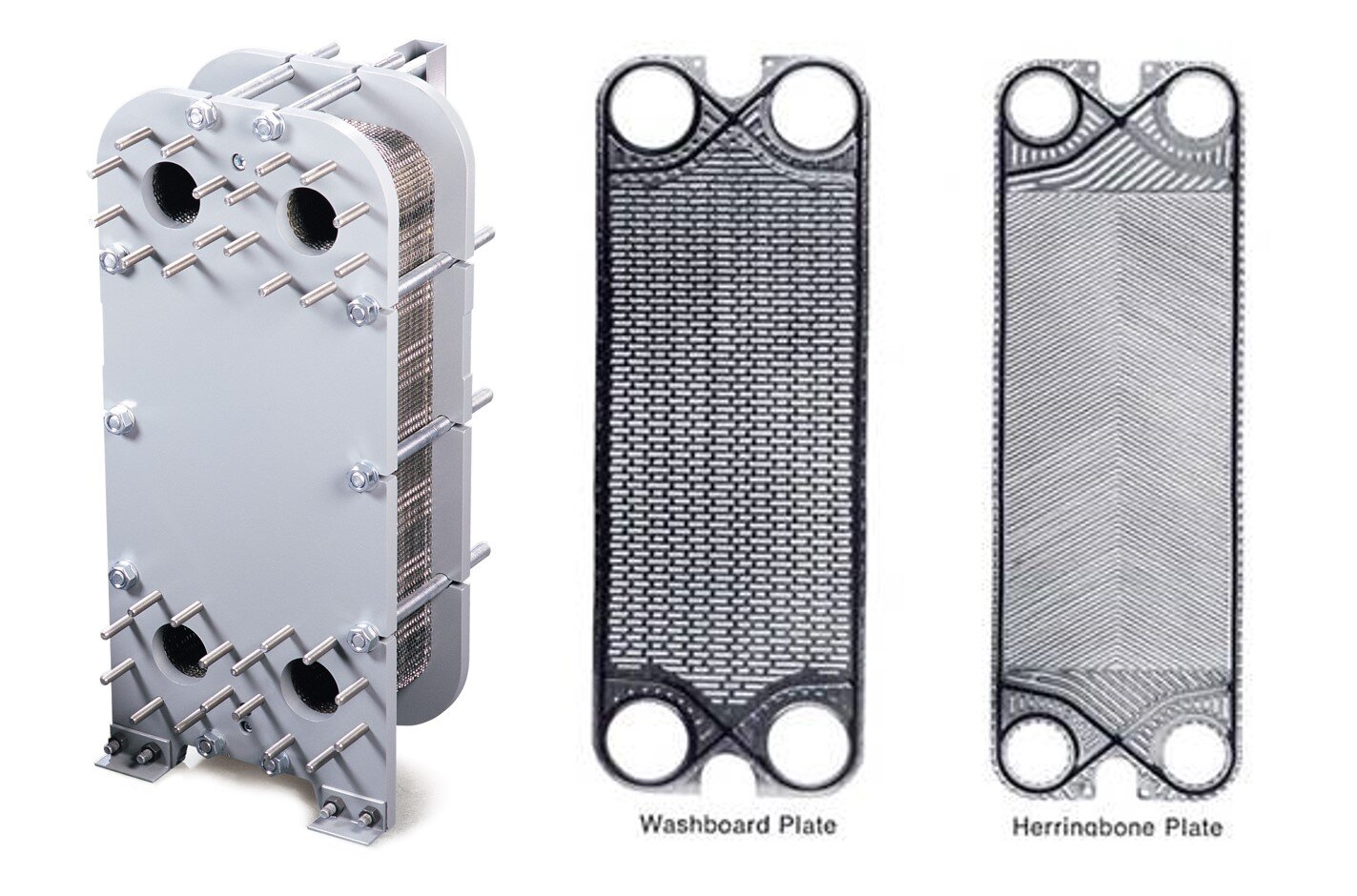

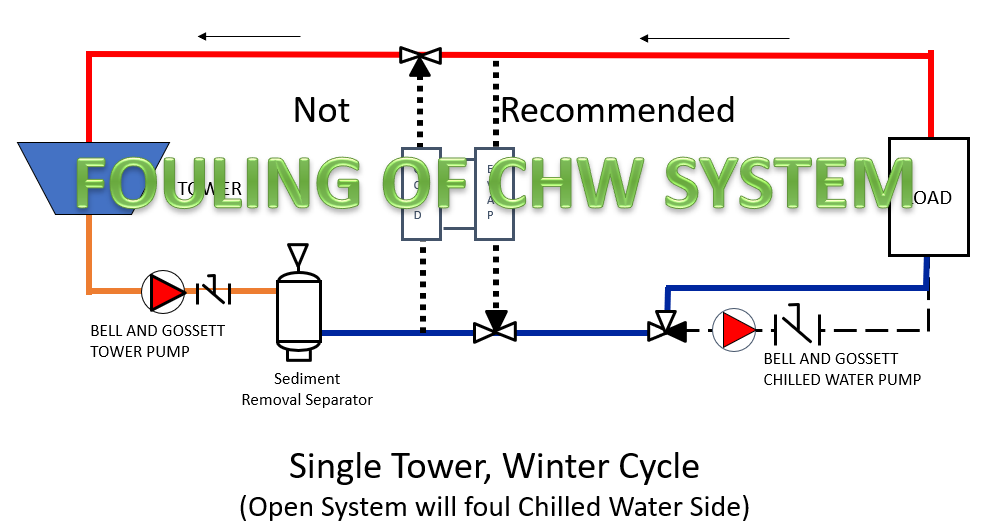

Waterside economizing typically involves the transfer of BTUs from an open loop cooling tower system to a closed loop chilled water system. Since these two hydronic systems must remain separate so we do not foul the chilled water systems, a heat exchanger is required to prevent mixing of the flu

plate & frame heat exchanger — HVAC Blog —

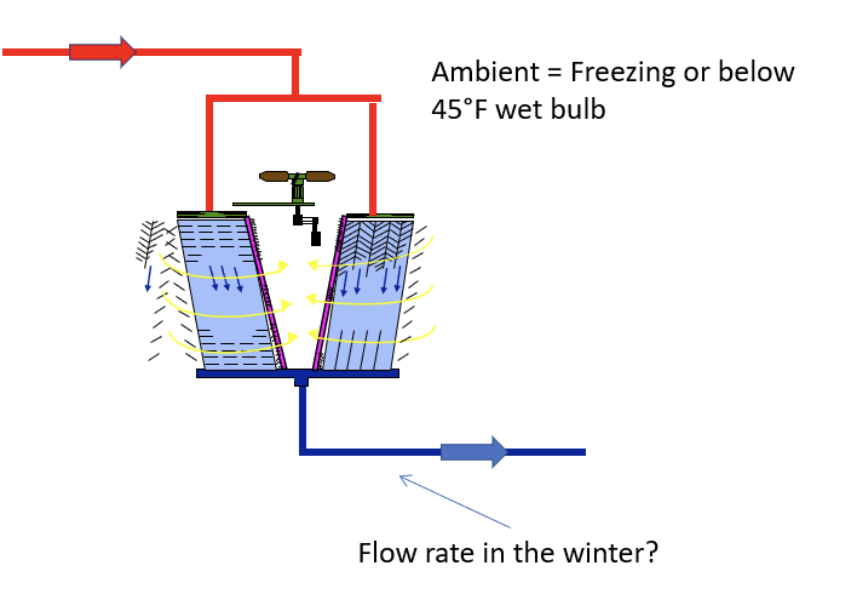

Designing Data Center Water-Side Economizers For Cold Climates: Part 1: Tower Sizing. - Document - Gale Academic OneFile

How To Size A Waterside Economizer Part 4: Chilled Water Piping Requirements —

Waterside Economizers Part 5: Heat Exchanger Location Options

waterside economizing — HVAC Blog —

Waterside Economizers Part 6: Tower Side Flow Rate

Waterside Economizing Series —

Waterside Economizer - NYCET

ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System Design, PDF, Heat Exchanger

Water Side Economizer Heat Exchanger Sizing and Selection